| Date: Mon, Feb 14, 2005 | Build Hours: 1 |

| Assembly: Empennage | Sub-Assembly: Inventory |

|

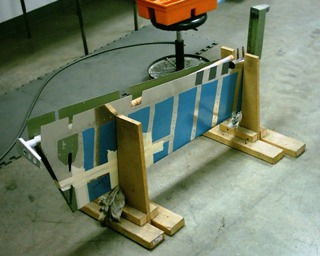

Alexander Technical Center: While I was on a business trip in the USA I made time to attended the empennage training at Alexander Technical Center, just south of Atlanta. Most of my Empennage was assembled only in 6 days.

Wow how much I have learned in these 6 days, I would recommend any RV first time builder to attend. They have a well equipped workshop with all the different types and makes of tools to try out and work with before you buy.

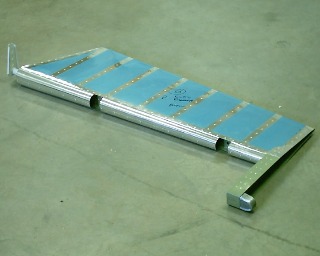

Inventory: I opened my High Dollar Aircraft part box and inventoried everything. It is amazing that the tail fits in such small boxes. | |